Infraprint provides 3D printing,

solutions for end users requiring engineered polymer and composites. The Infraprint team has extensive experience and expertise in the selection, design and printing of polymer, as well as short and continuous fibre reinforced composites for industrial end users. From the precision engineering, pharmaceutical reactors, protective sport equipment, aerospace and automotive components.

Additive Manufacturing

What is 3D Printing/Additive Manufacturing…

3D printing is a manufacturing technology that allows complex parts to be rapidly manufactured with low waste and without the need for costly tooling.

3D printing makes small batch and individualised parts more economically viable.

Infraprints patented 3Dprinting technology allows the printing of a wide range of engineering thermoplastics and composites.

Contact us today to discover how Infraprint can help …..

Contract Manufacturing

Mechanical Performance - 3D Printed Parts

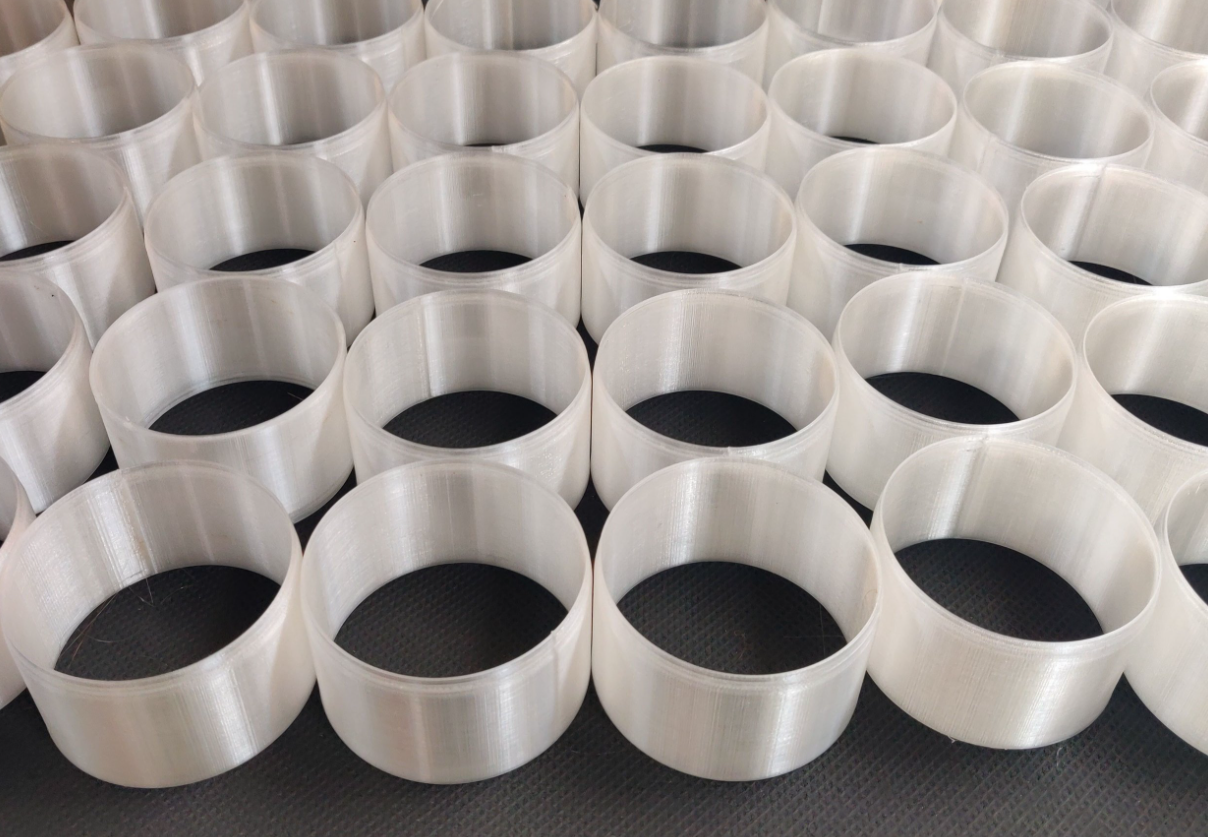

Infraprint offers contract manufacturing services to our customers. Producing some of the strongest 3D printed parts on the market.

Inhouse testing has demonstrated that TRAAM 3D printed PEI, PEEK and PEKK parts were up to 80% stronger in tensile tests compared to using conventional industrial 3D printers. Polymer parts printed using Infraprint’s proprietary printing technology (TRAAM), exhibit similar mechanical strengths to those obtained by injection moulding.

3D Printing Solutions

The Infraprint team has a combined 40 years of experience in 3D printing technologies and to-date have published over 30 academic journal papers on the results of their printing research. Their extensive knowledge of printing and printed material performance, uniquely positions the Infraprint team to advise and support customers in investigating the potential of 3D printing.

The team also has extensive expertise in designing and fabricating 3D printers, where conventional hardware solutions need to be modified to meet end use dimensional or material processing requirements.

The Infraprint Advantage

Infraprint has specialist expertise and capabilities in the 3D printing of engineering polymer and composite components. Previous experiences in working with customers in a range of industry applications areas, strongly positioning infraprint to investigate the potential of 3D printing for selected target applications.

Infraprint offers a contract manufacturing service for small batch production (1- 500 units), of polymer and composite parts with size of up to 70 cm.

infraprint is uniquely positioned for the deliver high performance printed engineering polymer and composite parts, due to its patented TRAAM technology. Thishas been demonstrated to produce PEEK, PEI and PEKK parts which are up to 80% stronger in the Z plane compared with those printed using conventional printed technology.

TRAAM parts exhibit similar mechanical performance to that obtained using injection moulding, but with all:

Complex Geometries

Internal Structures

Mass Customisation

Small Batch production

Our extensive materials testing has demonstrated TRAAMs effectiveness in printing a wide range of engineering polymers. With up to 82% greater tensile performance than current industrial grade printers on the market.

Materials Testing & Consultancy

Our experienced engineering team can assess your product needs. We can produce comprehensive material & process selection reports which can aid in your adoption of AM, saving you time and money.